低溫封裝玻璃粉2

Low Temperature Sealing Glass 2

Sealing glasses are composite materials made by blending matrix powder with a low softening temperature and specially synthesized ceramic filler powder. The sealing temperature and thermal expansion coefficient of sealing glass can be adjusted by changing the kind and blending ratio of the glass and filler.

LS-2010 is widely used for DIP and QFP made of alumina (thermal expansion coefficient: approximately 70×10-7/K).

LS-1401S is low sealing temperature of 380℃ makes it suitable for SMD packages for quartz oscillators.

LS-3051S is used for sealing low-expansion ceramics such as AlN (thermal expansion coefficient: approximately 45×10-7/K).

LS-1301 and BF-0901 are suitable for sealing silicon (thermal expansion coefficient: approximately 35X10-7/K).

Properties

| Usage | Alumina | AlN, Mullite ,Silicon | ||||||

| Properties/Glass Code | LS-1401S | LS-2010 | LS-3051S | LS-1301 | BF-0901 | |||

| Sealing temperature | ℃ | 380 | 435 | 430 | 450 | 560 | ||

| Dielectric constant | 1MHz,25℃ | 45.0 | 12.5 | 16 | 45.5 | 11.1 | ||

| tanδ | 1MHz,25℃ | ×10-4 | 38 | 34 | 41 | 60 | 19 | |

| Thermal expansion coefficient | 30℃-250℃ | ×10-7/K | 71* 1 | 65 | 51 | 41 | 49*2 | |

| Transformation point | ℃ | 258 | 313 | 303 | 315 | 430 | ||

| Softening point | ℃ | 355 | 400 | 390 | 390 | 528 | ||

| Density | ×103kg/m3 | 7.02 | 5.67 | 5.95 | 6.77 | 4.68 | ||

| Volume resistivity Log ρ | 150℃ | Ω•cm | 6.2 | 12.4 | 12.7 | 12.0 | 13.3 | |

| Thermal conductivity | W/m•K | 0.98 | 1.45 | 1.24 | 0.84 | 1.47 | ||

| Specific heat | ×103J/kg•K | 0.34 | 0.41 | 0.38 | 0.35 | 0.46 | ||

| Acid durability | 20%H2SO4, 70℃1min | mg/cm2 | - | 0.8 | 1.1 | 0.1 | - | |

| 10%H2SO4, 20℃10min | mg/cm2 | - | 0.5 | 0.9 | 0.1 | - | ||

| 10%HCI, 20℃10min | mg/cm2 | - | 1.9 | 2.7 | 0.5 | - | ||

| 10%HNO3, 20℃10min | mg/cm2 | - | 120 | 120 | 123 | - | ||

| Color | Black | Dark brown | Black | Black | Green | |||

| Glass type | PbO•B2O3(COM)*3 | Bi2O3•B2O3 (COM)* 3 | ||||||

- This thermal expansion coefficient was measured at 30 to 200 ℃

- This thermal expansion coefficient was measured at 30 to 200 ℃

- COM:Composite sealing glass

Application Method

1. Printing and Drying (except LS-1401S)

The paste for printing is prepared by adding vehicle to the powder glass and mixing them well. The vehicle is obtained by dissolving a low molecular weight acrylic resin in terpineol at a concentration of 5%. The paste obtained is printed on ceramic parts with an 80-100 mesh stainless screen. Printing and drying are repeated in order to increase the glass thckness of the film layer. Drying is carried out at 120℃ for 10-20 minutes.

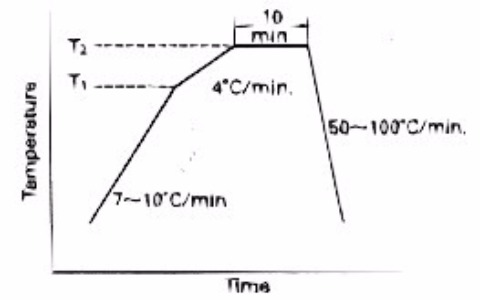

2. Pre-firing

In order to eliminate the resin in the film layer pre-firing is done in an oxidizing atmosphere such as oxygen or air. Decomposition and firing of the resin takes place most actively at 320-380℃, so gradual heating is necessary in this temperature range. Sintering of the powder glass is also carried out.

| Glass Code | T1 (℃) | T2(℃) |

| LS-1401S | 250 | 350 |

| LS-2010 | 320 | 390 |

| LS-3051S | 310 | 380 |

| LS-1301 | 310 | 400 |

| BF-0901 | 350 | 530 |

| Fig. 1 Pre-firing profile | ||

3. Lead-Frame Attaching

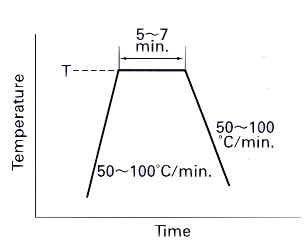

Lead-frame attaching is carried out in the air, and maintain the attaching temperature (T) for 5 to 7 minutes. When a heater block is used, the surface temperature of the block is kept higher than the attaching temperature by 30-50 ℃. Soak time is 1 to 2 minutes.

| Glass Code | T (℃) |

|

| LS-2010 | 435 | |

| LS-3051S | 430 | |

| LS-1301 | 450 |

Fig. 2 L/A profile

4. Sealing

Sealing is carried out in either an air or a nitrogen atmosphere. Soak time is approximately 10 minutes and temperature is the same as lead-frame attaching temperature. Heating up rate is 50 to 100℃/min. and cool down rate is 20 to 40℃/min.

5. Tin-Plating

Conventional tin-plating techniques are acceptable. Standard acid-cleaning and tin-plating conditions are as follows:

| Acid-cleaning | |||

| Steps | Solution | Temp. (℃) | Time (min.) |

| 1. De-scaling | 50%H2SO4 | 75-90 | 1.0-1.5 |

| 2. Acid rinse | 10-15% H2SO4 | 20-25 | 0.5-1.0 |

| 3. Water rinse | City water | 20-25 | 1.0 |

| 4. Water rinse | De-ionized water | 20-25 | 1.0 |

| Tin-plating | ||

| Method | Current density (A/dm2) | Time (min.) |

| Rack | 2.5-3.0 | 10 |

| Barrel | 1.0-2.0 | 15-30 |